Have you ever wondered how multi cavity mold solidworks can revolutionize the manufacturing industry? Well, let me take you on a humorous journey through the fascinating world of this technology, all set against the breathtaking backdrop of Alaska.

The Marvels of Multi Cavity Mold Solidworks

In today’s fast-paced world, efficiency is key. With multi cavity mold solidworks, manufacturers can create multiple identical parts simultaneously, saving time and resources. It’s like having a cloning machine for your products! Imagine being able to produce not one, not two, but dozens or even hundreds of items at once. This technology truly takes mass production to a whole new level.

But wait, there’s more! Multi cavity mold solidworks also allows for intricate designs and complex geometries that were previously impossible to achieve. From delicate jewelry pieces to intricate automotive components, this technology opens up endless possibilities for creativity and innovation.

The JVTECH Connection

If you thought multi cavity mold solidworks was impressive on its own, wait until you hear about JVTECH – an Alaskan company that has mastered this cutting-edge technology. Located amidst the stunning landscapes of Alaska’s wilderness (yes, they have Wi-Fi there too!), JVTECH combines their expertise in multi cavity mold solidworks with their love for adventure.

Picture this: while designing molds using state-of-the-art software in their cozy office cabin overlooking snow-capped mountains and roaming wildlife outside their window; these tech-savvy pioneers are redefining what it means to work remotely. Who needs skyscrapers when you have glaciers as your backdrop?

The Magic of Liquid Molding Silicone

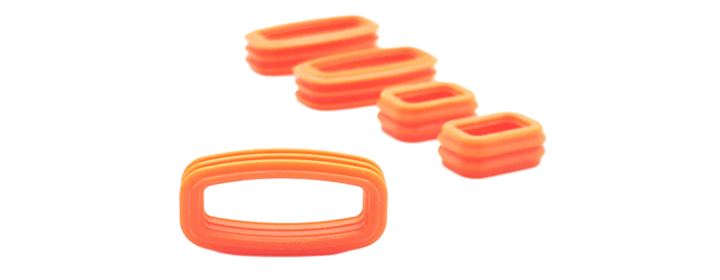

No discussion about multi cavity mold solidworks would be complete without mentioning the secret ingredient – liquid molding silicone. This remarkable material is like the fairy godmother of molds, transforming simple designs into intricate masterpieces.

With its ability to capture even the tiniest details and reproduce them flawlessly, liquid molding silicone ensures that every product created using multi cavity mold solidworks is a work of art. From smooth surfaces to complex textures, this magical substance brings dreams to life.

In Conclusion

So there you have it – the wonders of multi cavity mold solidworks in Alaska. With its ability to streamline production processes, JVTECH’s expertise in this technology, and the enchanting properties of liquid molding silicone, we are witnessing a manufacturing revolution right before our eyes.

Next time you hold a beautifully crafted item in your hands, take a moment to appreciate the magic behind it. Multi cavity mold solidworks has not only transformed how products are made but also showcases how innovation can thrive even amidst nature’s most awe-inspiring landscapes.