Understanding Water Based Ink

Water based ink has emerged as a preferred choice for various printing applications due to its eco-friendly nature and versatility. Unlike traditional solvent-based inks, which can release harmful VOCs (volatile organic compounds), water based inks utilize water as a primary solvent, making them environmentally responsible. Their wide array of colors and opacity levels allows for vibrant prints on numerous substrates, including paper and fabric. As sustainability becomes a significant concern for both consumers and manufacturers, opting for water based ink is a smart move for companies looking to enhance their green credentials while maintaining print quality. This transition not only aids in reducing the overall carbon footprint but also meets the increasing demand from consumers for responsible sourcing and manufacturing practices.

Advantages of Water Based Inks for Flexographic Printing

When it comes to water based inks for flexographic printing, they offer several advantages that enhance the efficiency and ecological soundness of the printing process. Flexographic printing is widely used in packaging, labels, and other materials, and water based inks ensure a lower drying time compared to solvent-based alternatives. These inks also provide excellent adhesion to substrates, resulting in sharp, detailed images without the need for harsh chemicals. Moreover, the reduced environmental impact of using water based inks aligns with modern industry standards that prioritize sustainability. Companies can achieve high-quality prints while being mindful of their ecological footprint. Real-world examples of brands successfully adopting these inks illustrate how they enhance product appeal and market reach, catering to environmentally conscious consumers.

Embracing Water Based Ink Screen Printing

For graphic designers and textile printers, water based ink screen printing offers a plethora of benefits that resonate with contemporary aesthetic demands. This method allows for intricate designs with striking colors, adhering seamlessly to textiles without compromising fabric softness. The water based formulations are known for their durability and wash-fastness, making them ideal for fashion and promotional items. Additionally, screen printing with water based inks generates minimal waste and is comparatively cost-effective, as the inks can be easily cleaned with water rather than harmful solvents. Many local brands have adopted this approach, transforming their products into environmentally friendly options that appeal to eco-aware customers. By integrating water based inks, these businesses not only boost their marketability but also contribute positively to the environment.

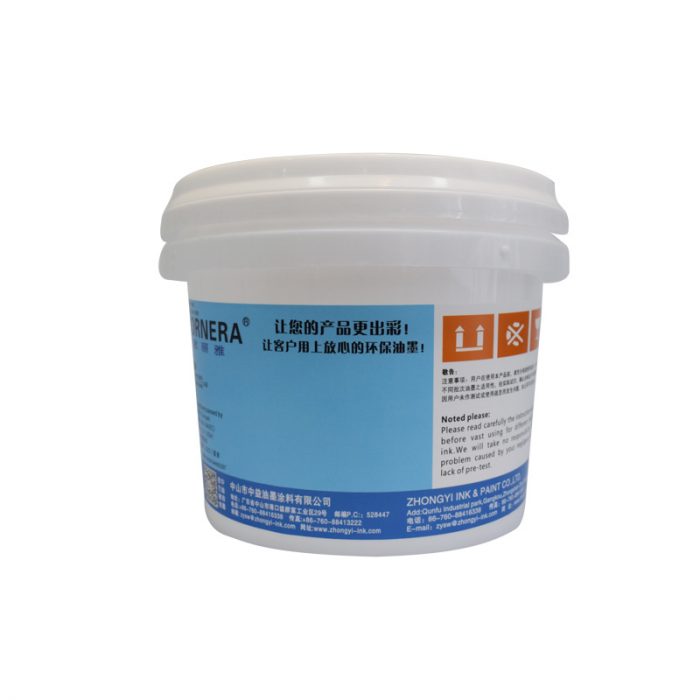

Conclusion: The Ideal Choice for Water Based Inks

In summary, water based inks present an environmentally friendly and versatile solution suitable for a variety of printing applications, including both flexographic printing and screen printing. The transition to these inks not only reduces ecological footprints but also meets quality excellence with vibrant results. Brands looking to stay ahead in a sustainable world would greatly benefit from working with a reputable manufacturer. For those seeking high-quality, sustainable ink solutions, Zhongyiink stands out as a trusted supplier with numerous advantages. Their commitment to producing top-tier water based inks ensures that businesses can achieve their printing goals while adhering to eco-friendly practices.